Operating Principles Of The Jaw Crusher

Industrial Solutions Jaw crushers ThyssenKrupp

Single-toggle jaw crushers design and operating principle Technical data Single-toggle jaw crusher Design Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being

Industrial Solutions Gyratory crushers ThyssenKrupp

Jaw gyratory crushers design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on

How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment

2022年6月8日All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped

Jaw Crusher Working Principle StudiousGuy

2021年9月17日A jaw crusher mainly works on the principle of reciprocating motion exhibited by the moveable jaw of the jaw crusher. The repeated movement of the jaws

What is a Jaw Crusher? MEKA Crushing Equipment

The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6. Settings and Damping Group 7. Hydraulic

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the...

Jaw crusher: types, principle and applications ResearchGate

PRINCIPLE OF JAW CRUSHER This jaw crusher uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make

Jaw Crusher Crushing Plant Hard Rock Mining

ROCK CRUSHER OPERATING PRINCIPLE: DOVE Jaw Crusher consist of the following main components, The Fixed Jaw Plate (Side Plate), Movable Jaw plate, Eccentric Shaft and Spring, Crushing Chamber,

The Working Principle of Jaw Crusher YouTube

2008年4月1日sbmchina This jaw crusher machine uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the triangle belt and...

Solved (b) Explain the operating principles of a jaw crusher

Solution: Operating principle of a jaw crusher The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes

Industrial Solutions Jaw crushers ThyssenKrupp

Single-toggle jaw crushers design and operating principle Technical data Single-toggle jaw crusher Design Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate.

Industrial Solutions Gyratory crushers ThyssenKrupp

Jaw gyratory crushers design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The

How Does a Jaw Crusher Work Jaw Crusher

All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts force on

Jaw Crusher Working Principle Animation YouTube

2019年1月18日Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other rec...

Jaw Crusher: Range, Working Principle, Application

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock. They crush primarily by using compression. The rock is dropped between two rigid pieces of metal, one of which then moves inwards towards the rock, and the rock is crushed because it has a lower breaking point than the opposing metal piece. 1 2 3 4

Jaw crusher: types, principle and applications ResearchGate

PRINCIPLE OF JAW CRUSHER This jaw crusher uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw...

Design and Construction of Rock Crushing Machine from

functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher. It forms the moving side of the jaw, while the stationary or fixed jaw forms the other. It achieves its movement through the eccentric movement of the crusher main shaft. It is the back and

The Working Principle Of A Jaw Crusher Editors Top

2014年12月25日The working principle of the jaw crushers is very simple. Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber. Stable performance and low operation cost; Even particle and large crushing ration. The jaw crushers can be used for crushing all kinds of hard materials quickly and efficiently.

Jaw Crusher Operation Principle Camelway Machinery

2018年4月18日Jaw Crusher Operation Principle. The jaw crusher is the main component of the crushing plant. It incorporates an electrical motor to dive a rotating shaft that throws the stones and rocks. Inside the chassis of the machine, there are two or tree impact plates where the rocks and stones impact and are broken to obtain smaller parts.

The Working Principle of Jaw Crusher YouTube

2008年4月1日sbmchina This jaw crusher machine uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the triangle belt and...

Download Ebook Jaw Crushers Operation Manuals

Principles of Mineral Processing Operator's Manual for Crusher, Jaw, Diesel and Electric Driven, Wheel Mounted, Pneumatic Tires, 75 Ton Per Hour, Eagle Crusher Model 5157 and 5157A (NSN 3820-00-783-7311), Eagle Crusher Model 5157B (NSN Jaw Crushers Operation Manuals, it is no question simple then,

Hengtong 2023 Jaw Crusher Factory Direct Sale

Operating Principle This jaw crusher uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track. Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and side-lee board can be crushed and

Jaw Crusher an overview ScienceDirect Topics

operating characteristics such as the length of stroke, the number of strokes per minute, the nip angle. Mathematically, the capacity can be expressed by the general formula (4.8) where Q = capacity w = width L = height (or depth of jaws) LMAX = set maximum (open set) LMIN = set minimum (closed set) LT = length of stroke or throw

Blake Jaw Crusher Mineral ProcessingMetallurgy

2016年1月15日The original Blake crusher was designed with a vertical stationary jaw. Probably the first departure from this arrangement was an 84 X 66″ crusher, built in 1914. This machine conventional design, in that the swing jaw was made vertical. Later, when the Superior line was developed, a compromise between these two extremes was used in

Industrial Solutions Jaw crushers ThyssenKrupp

Single-toggle jaw crushers design and operating principle Technical data Single-toggle jaw crusher Design Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate.

Jaw Crusher Working Principle Animation YouTube

2019年1月18日Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other rec...

Jaw Crusher: Range, Working Principle, Application

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock. They crush primarily by using compression. The rock is dropped between two rigid pieces of metal, one of which then moves inwards towards the rock, and the rock is crushed because it has a lower breaking point than the opposing metal piece. 1 2 3 4

What Are Jaw Crushers and How Do They Work?

2019年3月28日March 28, 2019 / in News. A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks. The equipment was first introduced back in 1858 by inventor Eli Whitey

Jaw Crusher Operation Principle Camelway Machinery

2018年4月18日Jaw Crusher Operation Principle. The jaw crusher is the main component of the crushing plant. It incorporates an electrical motor to dive a rotating shaft that throws the stones and rocks. Inside the chassis of the machine, there are two or tree impact plates where the rocks and stones impact and are broken to obtain smaller parts.

Design and Construction of Rock Crushing Machine from

functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher. It forms the moving side of the jaw, while the stationary or fixed jaw forms the other. It achieves its movement through the eccentric movement of the crusher main shaft. It is the back and

The Working Principle of Jaw Crusher YouTube

2008年4月1日sbmchina This jaw crusher machine uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the triangle belt and...

The Working Principle Of A Jaw Crusher Editors Top

2014年12月25日The working principle of the jaw crushers is very simple. Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber. Stable performance and low operation cost; Even particle and large crushing ration. The jaw crushers can be used for crushing all kinds of hard materials quickly and efficiently.

Download Ebook Jaw Crushers Operation Manuals

Principles of Mineral Processing Operator's Manual for Crusher, Jaw, Diesel and Electric Driven, Wheel Mounted, Pneumatic Tires, 75 Ton Per Hour, Eagle Crusher Model 5157 and 5157A (NSN 3820-00-783-7311), Eagle Crusher Model 5157B (NSN Jaw Crushers Operation Manuals, it is no question simple then,

Blake Jaw Crusher Mineral ProcessingMetallurgy

2016年1月15日The original Blake crusher was designed with a vertical stationary jaw. Probably the first departure from this arrangement was an 84 X 66″ crusher, built in 1914. This machine conventional design, in that

2023 Jaw Crusher Mobile Rock Crusher/Stone/Rock/Gold/Copper

Operating Principle This jaw crusher uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track. Therefore, the materials in the crushing cavity composed of fixed jaw plate, movable jaw plate and side-lee board can be crushed and

Download File Jaw Crushers Operation Manuals Pdf

Jaw Crushers Operation Manuals, it is categorically simple then, past currently we extend the member to buy and create bargains to download and install Jaw Crushers Operation Manuals in view of that simple! principles and practice of mineral processing, with examples taken from practice

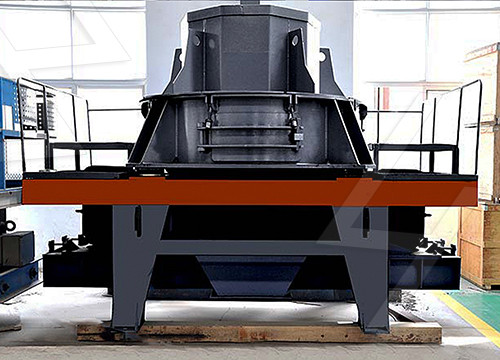

How Vertical Shaft Impact Crushers Work Mellott

2023年2月24日By utilizing the principles of rock-on-rock crushing, they effectively reduce material size while producing minimal dust pollution and creating desirable grain shapes. To learn more about how you can use vertical shaft impact crushers to help you with your next project, reach out to the Mellott Company team of experts today at 855-554-1606 .